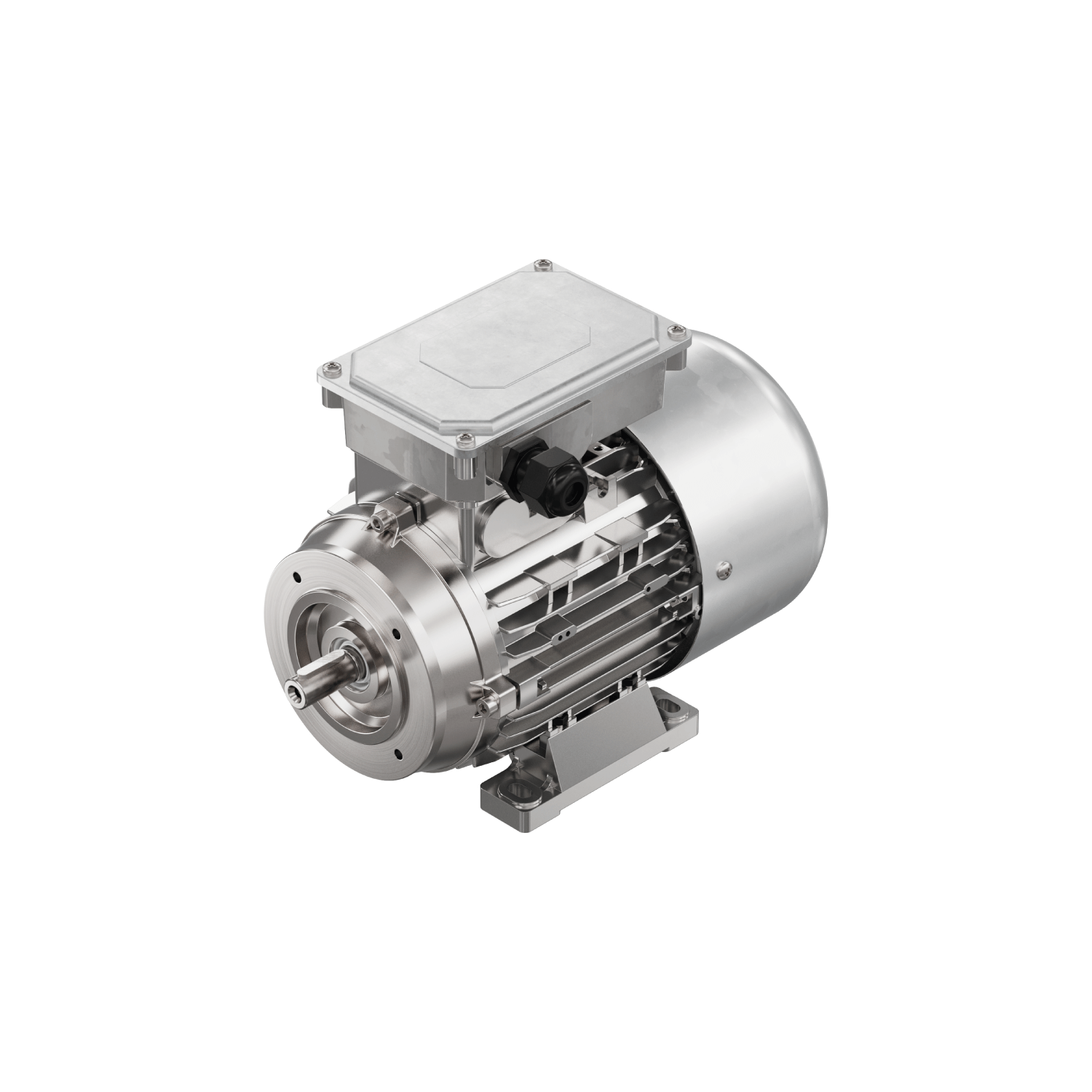

General product features

Especially for larger screw jacks and systems, we recommend the use of a frequency converter to achieve smooth start-up and brake ramps. This minimizes start-up noise and extends the service life of the gearbox.

When operating with a frequency converter, remember that if the motor is to be operated for extended periods at frequencies less than 25 Hz, its fan must be driven separately. This is necessary to ensure adequate motor cooling. When operating a braked motor with a frequency converter, a separate actuation line for the brake must be provided via the frequency converter.

Braked motors

We recommend using a braked motor to minimise the overrun time of the system. Where a screw jack is fitted with a ball screw or a double-pitch screw, a braked motor is absolutely essential. We supply motor brakes as standard for a connection voltage of 230V AC / operating voltage 205V DC, with bridge rectifiers.

Other connection voltages (24V DC, 400V AC, 500V AC) are available on request.

Temperature monitoring

Generally we do not supply temperature monitoring because screw jack duty cycles are normally quite low or the motor is adequately dimensioned. Most standard motors above 1.5 kW are equipped with PTC.

Versions with bimetal switch (TH), Temperature control thermal resistor PTC (TF) and combined are available on request.