| 200 kN | |

| 1500 rpm | |

| 3000 rpm | |

| 70x12 | |

| GGG-50, corrosion-resistant | |

| Steel, case-hardened, ground | |

| 50 kg | |

| 32 kg | |

| Synthetic fluid oil | |

| Grease lubrication | |

| max. 60°, higher on request | |

| N: 11.5 kg cm² / L: 7.99 kg cm² | |

| max. 155 Nm (N) / max. 39.3 Nm (L) | |

| max. 770 Nm | |

| Rotating (R) |

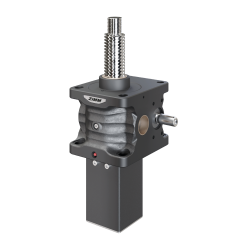

R-Screw | rotating

The spindle is fixed to the worm wheel and rotates with it. The nut therefore moves up and down.

S-Screw | translating

The worm wheel has an internal thread and transforms rotary motion into linear movements as long as the spindle is prevented from rotating.

Pivot bushes are incorporated in the gearbox housing for screw jack series ZE, ZE-H and Z. Swivel bushes can be subjected to the full nominal load with either compression or tension.

Placement

5kN – 25kN | Front and rear side

35kN – 1000kN | Lateral

| Lubricate the ball screw KGT every 300 hours of effective operation. For heavy-duty systems every 100 hours. | |

| Inspect the trapezoidal screw regularly and regrease it depending on the operating cycle. |

Depending on areas of use, through holes or blind tapped holes are advantageous.

A safety nut is specially applied in such cases where the rupture of the screw may be of danger for people. Safety nut may also be used in other devices to protect against damage of machinery and outages.

Wear

After a maximum of 25% of the thread is worn out, the support nut (R) or the gear (S) needs to be replaced.

Monitoring

It is necessary to perform periodic checks and to record the wear or the thread alignment (according to the time in operation). This enables to plan the replacement soon enough to avoid the outage of the equipment.

Electronic monitoring

Electronic monitoring will signal when the approximate level of 25% wear is reached and this could be immediately displayed at the central location. Wear parts replacement may be organised in a timely manner.