General product features

The ZE-Series takes the state of the art Zimm screw jacks to the next level with these industry leading advantages:

- Zimm’s dual lubrication system: Provides separate spindle and gearbox cavities allowing for optimum lubrication type to be used in each with the new ZE-Series having a larger gearbox capacity for grease and now oil for longer duty cycles. Separate cavities also completely eliminate lubrication cross contamination in the gearbox

- Smoother and modern streamlined design: Provides increased heat dissipation, easier paint and corrosion application as well as enhanced wash-down suitability

- Robust gearbox design allows full capacity mounting in any position

- Hardened and ground worm shaft is standard

- Reduced backlash from advanced worm gear design and machining techniques

- Compatible with existing Z-Series

- Available in 10 sizes | 5kN – 350kN

Discover the appropriate spindle for your application

The parameters and requirements for the application of your lifting gear are crucial when choosing either a trapezoidal thread or ball screw, especially concerning the following:

- Duty cycle

- Repitition accuracy and positioning accuracy

- Stroke speed

- Stat. / dyn. loading (Hold load in position or move)

- Service life and maintenance

Characteristics_Trapezoidal thread or ball screw

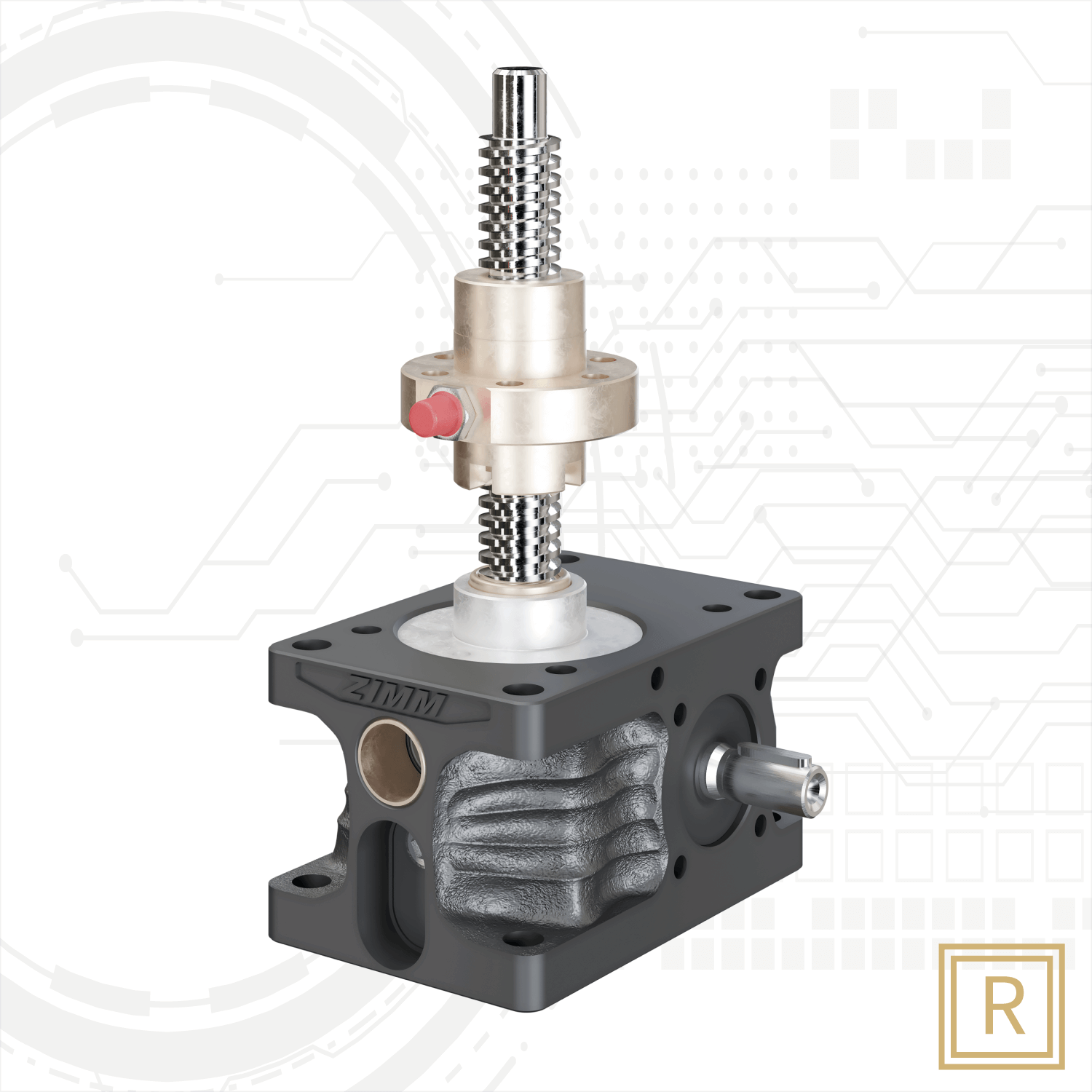

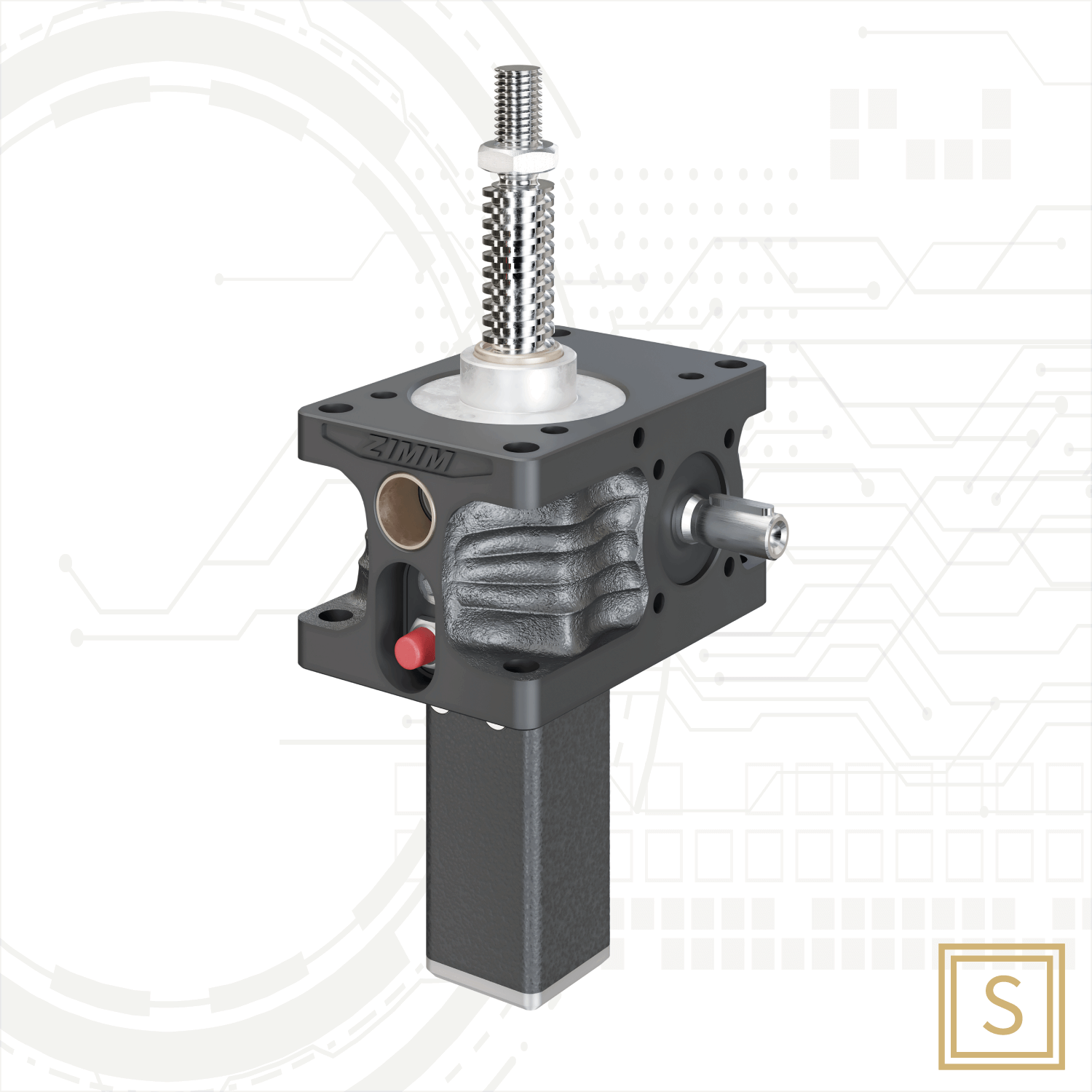

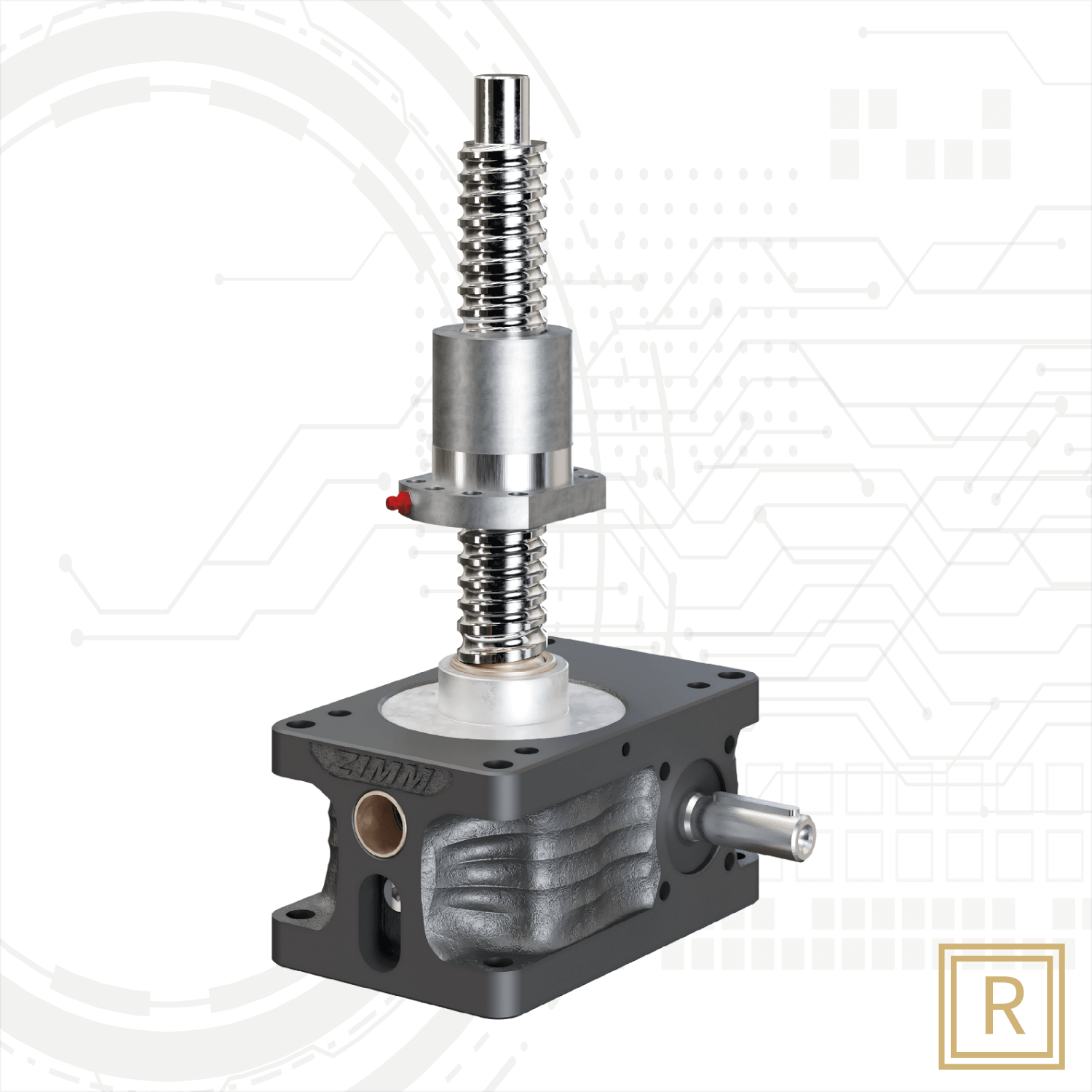

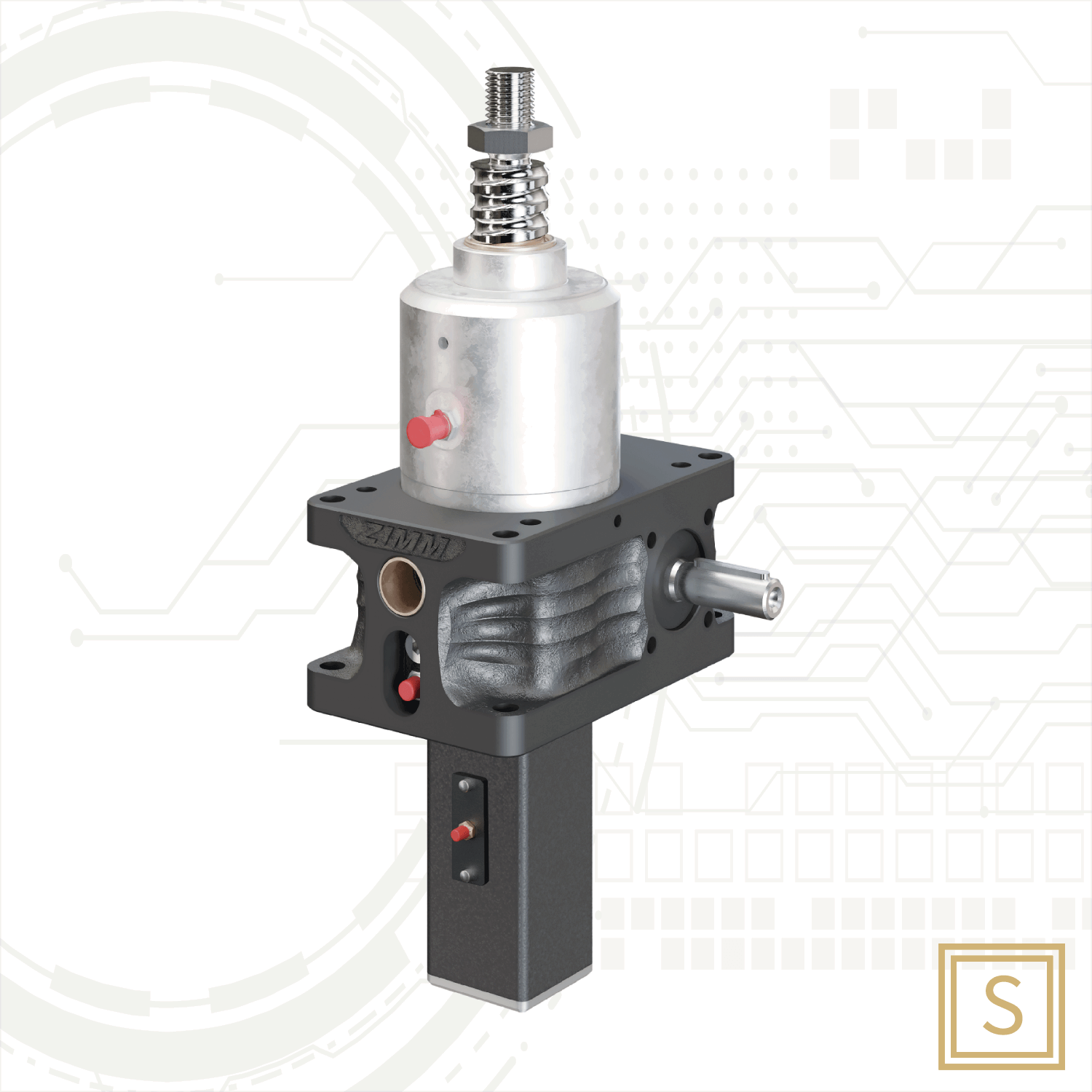

Functionality | Rotating and translating spindle

R-Screw | rotating

The spindle is fixed to the worm wheel and rotates with it. The nut therefore moves up and down.

S-Screw | translating

The worm wheel has an internal thread and transforms rotary motion into linear movements as long as the spindle is prevented from rotating.